5 five-axis milling machines

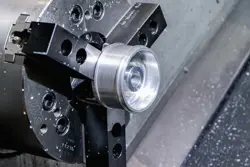

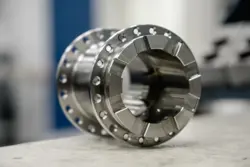

Kitamura Mytrunnion 4G. X500 Y500 Z450. Equipped with 60 tool stations, spindle probe, and table probe. Features fully simultaneous 5-axis milling for advanced and precise machining.

Our manufacturing department is one of the most flexible and competent in the area, allowing us to offer delivery with competitive lead times.

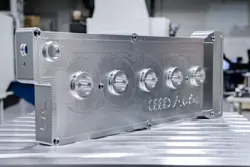

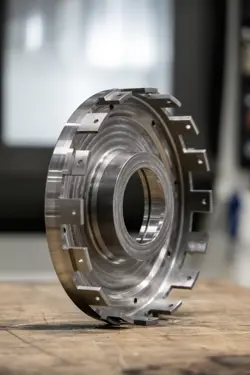

Need to produce a small series in a short time? Hiltec manufactures single components or small series in sizes up to 2,500 x 840 mm. We take full responsibility for the entire project, from drawings and surface treatment to final delivery. Our facility includes several 5-axis milling machines and a multi-machine for handling complex components.

We work with all types of materials, including plastic, stainless steel, copper, steel, and aluminum. With additional services such as hardening, painting, and various surface treatments, we are often the only partner you need to ensure the success of your project.

Creating a prototype starts with an idea and a vision. Sometimes, we are involved early in the process, working closely with the customer to develop a technical drawing. This concept then evolves into a physical model, which we machine in-house. Of course, we can also begin prototype manufacturing based on a drawing provided by the customer.

Regardless of the approach, we develop a prototype that can be modified and adjusted as needed, ultimately creating a model that serves as the foundation for the final tool.

We have the capacity to produce all types of components, regardless of shape or complexity, and work with a wide range of materials such as plastic, stainless steel, copper, steel, and aluminum. By also offering hardening, painting, and various surface treatments, we can manage the entire process from start to finish. This allows us to deliver your order with short lead times—without compromising on quality or precision.

Kitamura Mytrunnion 4G. X500 Y500 Z450. Equipped with 60 tool stations, spindle probe, and table probe. Features fully simultaneous 5-axis milling for advanced and precise machining.

Cincinnati FTV. X2540, Y815, Z800. Spindle speed up to 10,000 RPM. Equipped with 50 tool stations. Maximum part length: 3800 mm. Maximum width: 1200 mm.

Bed cutter

Lagoon BM4 X4000 Y1300 Z1500

Correa X2500 Y900 Z600

Cincinnati CFV i. X1050-Y540- Z560. S10000. Spindle test, on-board test.

HAAS VF-2SSYT. X762 Y508 Z508. Spindle speed up to 12,000 RPM. 40 tool stations, spindle probe, and table probe. Openable side panel.

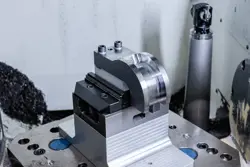

Multi-op

HAAS VF-2. X762 Y508 Z508. Spindle speed up to 12,000 RPM. 24 tool stations, spindle probe, and table probe. Openable side panel.

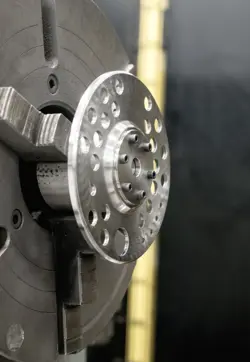

HAAS ST-30Y Ø584 Z457. Spindle passage Ø76 mm S3400. Y-Axis MovementY±50,8 mm. S3000. Milling length 400 mm between centers. Guided C-axis. (Chuck) Driven tools.

Profila 12" Over cross slide Ø350. Over bed Ø630. L 2500. Removable gap. Ø900 L 300. Spindle passage Ø74 mm.

5 pieces Edge Cam

Fanuc Robocut a – 1iE. Board surface X600 Y400 Z310

Marker board, 100x100x50 mm (LxWxH) up to 40%.

Feel free to fill in the form if you want to get in touch with us, whether you have questions or want help with a project.

Processing of Personal Data

When you submit an application to Hiltec, we process your personal data in accordance with GDPR. The data is used to manage the recruitment process and is only stored for as long as necessary. For more information on how we process personal data, please see our Privacy Policy. Integritetspolicy.